The Industrial Metaverse is the bleeding edge of Industry 4.0. It is the convergence point for the new and current technologies such as machine learning (ML), virtual reality (VR), augmented reality (AR), internet of things (IoT), artificial intelligence (AI) and digital twins, that are revolutionising the ways we work, plan and build. It will be the means by which complex industrial processes can be simplified and made more efficient.

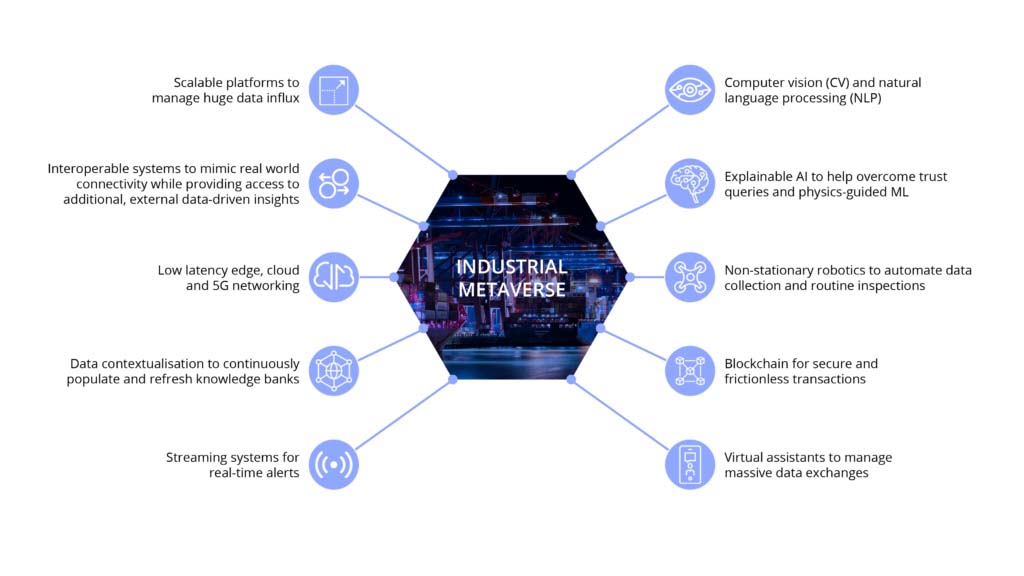

The diagram below shows the various technologies that provide the pillars to make the Industrial Metaverse possible.

Whilst we still have a little way to go before we have a fully realised and open metaverse across all industry, it is widely accepted as the future of operational technology and there is a strong case for arguing that the Industrial Metaverse will enable the sector to achieve the following:

- Reduction and ultimately eradication of human error.

- Control over unpredictability.

- Provide the greatest means to reduce climate impact across many industries.

- Help to save and safeguard lives.

Let’s take a closer look at each of these statements as well as some use cases that are already in existence.

Reduction and ultimately eradication of human error

- Best practice from across the globe can be gathered, analysed and scrutinised to reveal even better means of operating.

- Intelligent systems will be able to identify issues that the human eye misses or cannot gain access to see.

- Persistent, connected platforms will not need downtime and will be highly reliable.

- Efficient, intelligent and predictive operating systems will lead directly to lower operational costs.

- The Industrial Metaverse will actually allow us to extract massive benefits from data, faster and in ways that are simply not possible otherwise.

Trainees and employees can be trained quickly and safely through immersive learning practices that are offered by VR. Mistakes can be made in these graphically detailed virtual environments without any risk to life or property so practice procedures can be run continuously until peak performance is achieved.

Control over unpredictability

- The Web3 technologies that form the bedrock of the Industrial Metaverse enable an interconnected, immersive, predictive and persistent ecosystem.

- We will be able to use it to assess countless ‘what if’ scenarios, test different hypotheses and predict future outcomes.

- The tools of the Industrial Metaverse will arm us with the most accurate early warning systems and give us the means to better prepare so that nothing is left to chance.

- Decision-support and concrete planning will be accessible to everyone from governments to individuals.

Decision-support tools such as Single Synthetic Environments (SSEs), which are high fidelity simulations, provide vital insights for planning activity as they enable the running of countless what-if scenarios to reach the ideal action recommendation that mitigates risk or error. SSEs can also be used for stakeholder management, by giving relevant participants the ability to visualise and virtually experience the planned project or infrastructure, you can better secure buy-in ahead of the project kick-off.

Provide the greatest means to reduce climate impact across many industries

- Enterprises that transition to this new mode of operations will secure their sustainability goals and move ever closer to a net zero target.

- It will provide massive waste reduction benefits as we will be able to remove unnecessary physical production out of the equation.

- Designs and prototypes can be re-made as many times as required to reach the optimal end product and then built once.

- The Industrial Metaverse directly contributes to cleaner transportation and cleaner energy as it supports more efficient methods of operating.

- Greater interconnectivity will mean that people will be able to collaborate from anywhere in the world resulting in less requirements to travel.

Digital twins that represent real industrial machinery and environments can be used to model and assess how energy consumption and emissions can be reduced within operational processes. Multiple scenarios, using the digital twin and AI, can be tested to gauge the most efficient methods for reaching sustainability and climate impact reduction goals.

Help to save and safeguard lives

- We will be able to visualise, assess and diagnose with much greater accuracy.

- New therapies can be tested quickly and safely.

- Emergency response times will be shorter and performed with greater efficiency.

- Burdens on healthcare provision will be lifted as capabilities are improved.

- Learnings and new discoveries can be quickly disseminated.

- There will be better preparation for, as well as advanced warning of, disaster incidents.

Conjoined twins in Brazil were successfully separated, thanks to the use of VR, in one of the most complex operations in recent times. Surgeons were able to view the anatomy of their patients and practise the procedure using the technology, meaning that they were highly prepared before the real operation.

How to approach the Industrial Metaverse

Technology innovation leaders wanting to harness the enabling technologies of the Industrial Metaverse will need to evaluate the growth of these emerging technologies and trends that are enabling operational metaverse experiences to see which opportunities make the most sense for their organisations then decide on timelines for adoption.

They can explore metaverse use cases, such as the examples provided above, for opportunities to better deliver targeted business outcomes that they are currently focused on, or create totally new business models and ways of working.

Continuous identification of opportunities, obstacles and business impact for industrial metaverse technologies will be fundamental as they build out their organisation’s transformation framework.

For guidance on how to plan out your metaverse strategy, register for Hadean’s Metaverse Academy. The Academy offers learning pathways that will be continuously updated to offer the most up to date learning experiences for brands and enterprises looking to enhance their performance and output through the metaverse.